Giddings & Lewis boring mills are widely recognized as the most rigid and precise machining platforms in the industry. With unrivaled accuracy and the ability to meet the tightest tolerances, these machines deliver the highest possible quality results, every time. Not sure which one is right for you? Our expert engineers will work with you to find the perfect solution from our flexible, modular range.

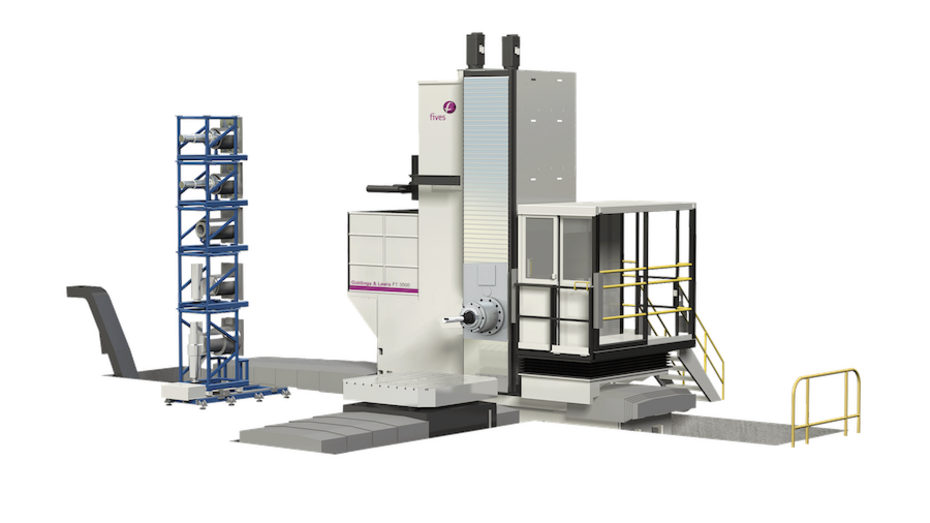

Giddings & Lewis FT 3500

Heavy duty engineering for demanding operations

The Giddings & Lewis FT 3500 is a large precision boring mill, designed for the most demanding applications in heavy industry.

Engineered to offer superior stiffness and thermal stability, this machine can make accurate, heavy cuts to produce parts for bulldozers, cranes, power generators, mining shovels, airplanes and oil rigs.

Equipped with a standard boring mill live spindle, the Giddings & Lewis FT features programmable boring bars and contouring heads to add machining versatility and reduce the number of tools needed. Automated attachment-changing optimizes efficiency and reduces cycle times. Even large attachments can be automatically changed.

The Giddings & Lewis FT 3500 has an entirely modular design, which means you can select the features and capabilities you want, based on your application requirements.

- All new components

- Cast iron machine base

- Preloaded roller guide

- Choice of travels, headstocks, controls and tool capacity

- Infinitely-variable spindle drive

- Safe and convenient operator platform

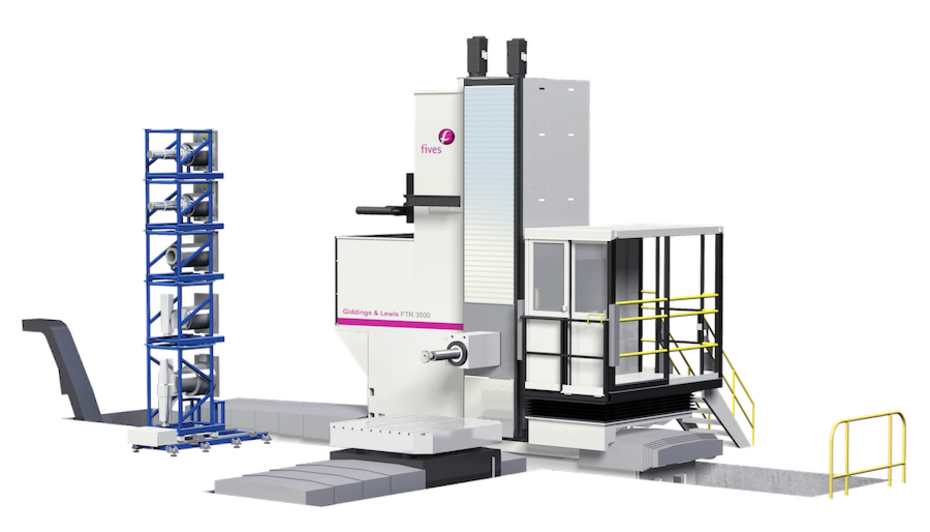

Giddings & Lewis FTR 3500/5000

Solid performance with added capabilities

In addition to the standard boring mill live spindle, the large, heavy-duty Giddings & Lewis FTR 3500/5000 models have a rectangular ram for extended reach and rigid cutting performance capabilities.

Designed with a single-piece cast iron bed, Giddings & Lewis boring mills provide exceptional rigidity and unrivaled accuracy. The inherent high stiffness in the machines guarantees a reliable performance over and over again, with minimal downtime.

Offering fully automatic tool changing capabilities, these machines are highly efficient and have minimized part machining cycle time. A good investment, they deliver high productivity with a low cost of ownership.

Designed with a modular set-up, the Giddings & Lewis FTR 3500/5000 models can be fully customized to meet the needs of your individual application.

- Cast iron machine base

- Preloaded roller guide

- Collinear ram in addition to live spindle

- High performance drive/way system

- Safe and convenient operator platform

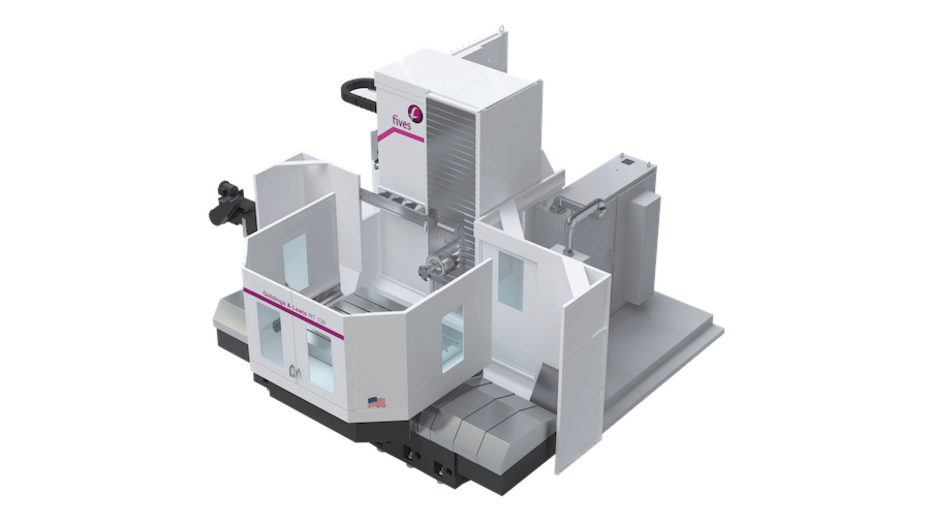

Giddings & Lewis MC 1250/1600

Flexible automation for heavy industry

The Giddings and Lewis MC Series of horizontal boring mills offers the ultimate performance in automated large part production.

With a one-piece column base and bed, these rigid machining platforms deliver exceptional stiffness for precise, heavy cuts. Accuracy is further enhanced by the capability to probe with either the main spindle or an auxiliary probe. These machines are ideal for industries such as oilfield, defense, aerospace and construction, where high precision in the boring of large workpieces is crucial.

High precision doesn’t need to mean reduced efficiency. With a fast traverse rate of 25 m/min, as well as fully automatic tool-changing capabilities and a dual pallet shuttle, the Giddings & Lewis MC 1250/1600 models achieve exceptionally high productivity rates.

Flexibility is a key feature of these machining centers. The machines are crafted with an entirely modular design, so we can work with you to create a custom machine that combines the features and capabilities that you need, based on your application requirements.

- Single-piece cast bed

- Programmable boring bars

- Programmable contouring heads

- Minimized number of tools needed

- Fully automatic tool changing

- Industry leading traverse rates

Giddings & Lewis PT 1500/1800

High stiffness and ultimate versatility

The Giddings & Lewis PT Series of horizontal boring mills are ideal when high flexibility is required to process a wide range of parts.

Designed with a modular setup, you can choose from three different headstocks (two or four-speed, 130 or 155 mm diameter). Capabilities can be expanded with the addition of rotary tables or attachments, such as contouring heads and programmable boring bars.

Giddings & Lewis are renowned for producing the most rigid and accurate machining platforms in the industry. The PT Series machines have a stiff machining platform, comprising a one-piece column base and bed. In addition to high precision, high stiffness gives thesemachine tables a substantial weight capacity, with the ability to handle parts weighing as much as 40,000 kg.

The Giddings & Lewis PT 1500/1800 boring mills feature preloaded roller guide ways, which offer significant advantages over other types of way system.

Benefits include:

- Double the load capacity and up to 10 times the life of ball-type linear ways

- Lower friction

- Enhanced positioning accuracy

- Better circular/contouring accuracy

- Low thermal growth for more consistent accuracy

- Low maintenance and ease of repair

Giddings & Lewis RT 1250/1600/2000

High precision for heavy components

The Giddings & Lewis RT Series of boring mills are designed for exceptional versatility, making them a smart choice for a wide range of industries, including aerospace, automotive, mining and defense.

A modular set up means that you can choose the features and capabilities that you need for your individual production process.

With a built-in contouring rotary table and an additional axis, these machines are ideal for boring prismatic parts that require work on multiple surfaces. Meanwhile, the one-piece rigid machining platform, which is characteristic of all Giddings & Lewis boring mills, makes easy work of heavy, high-precision cuts.

The Giddings & Lewis RT 1250/1600/2000 models are robust, heavy duty boring mills with a substantial weight capacity. They can handle any part weighing up to 40,000 kg.

Advantages of table-type horizontal boring mills include:

- Rigid machining platform with one-piece column base and bed

- High performance drive and way system

- Flexible design

- Fast traverse rates of up to 25 m/min

Giddings & Lewis T-Bed 130/155

Maximum productivity at minimum cost

The Giddings & Lewis T-bed horizontal boring mills are an efficient, cost effective solution to your cutting needs.

The machines offer the signature high stiffness, accuracy and reliability of the Giddings & Lewis brand, at a price point that is appealing to a wide range of industries.

Reduced cost does not mean reduced quality. Constructed from cast iron with a cross-braced column, these are ridgid boring mills that are made for heavy duty precision cutting. Large linear rails with heavy duty roller carriages and linear scales provide a precise, low friction system that can withstand high thrust. Machine stiffness is further enhanced by the 10 ton hydrostatic table, which offers 360 degree clamping. Meanwhile, the electronically-counterbalanced headstock delivers a superior contouring performance.

The Giddings & Lewis T-Bed 130/155 boring mills offer high flexibility and can be customized to meet your individual machining requirements. A variety of attachments and probes are also available to further increase versatility.

Further advantages of the Giddings & Lewis T-bed 130/155 models include:

- Dual servo B-axis table, electronically compensated for zero backlash

- Small footprint

- Flat floor installation for reduced foundation and installation costs

- Economical chip management

- Integral coolant pan for chip and coolant containment